We did further work as can be seen below. After this we met up for the final design review. There were some software/electronic-issues – Ultra sonic sensor that gave wrong read-outs in certain situations.

The general feedback was positive and most of the critique were of a sort that we were already aware of.

C & F

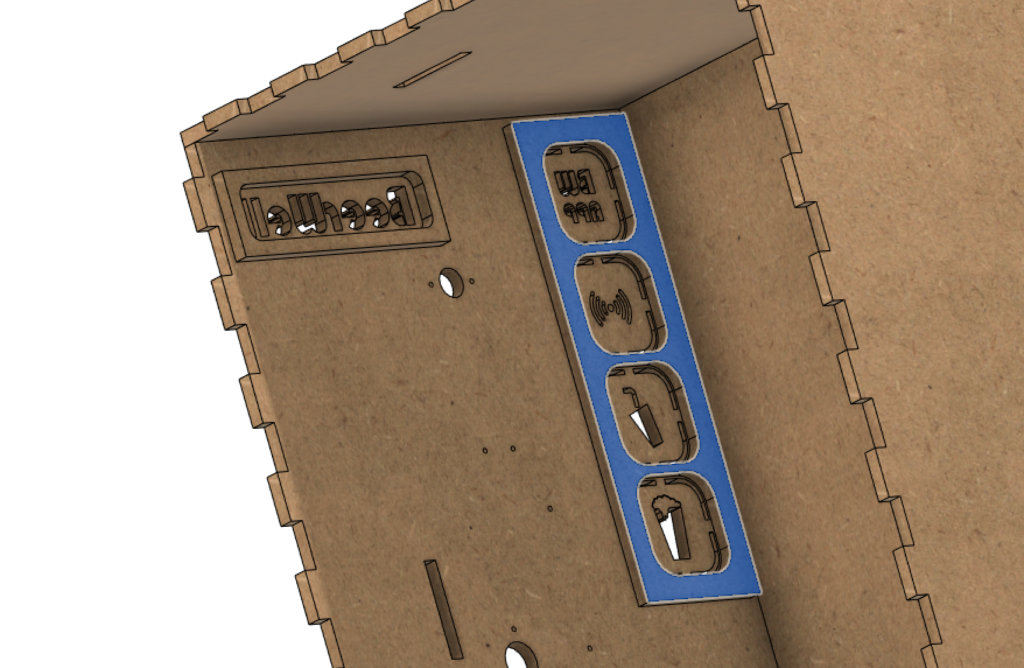

We started the day laser cutting the final prototype. We included a QR code on the front functioning as a download link for the app.

After the first cut outs we realized that the front plate needed some adjustments. We adjusted some dimensions and to added and moved different holes to facilitate better placement of electronics.

We found out that the mounting plate (in the center) covered some of the front logo. Therefore we did a small manual cut out afterwards.

We also produced an aluminum drip tray to test this functionality and assembled it into the prototype frame. It worked, but we can se the potential in creating a drip tray that functions as a full depth drawer that can be extracted from the back of the BeerWell. This would result in a larger drip tray, easier construction, less material consumption, fewer parts and better usability.

We also lasercut some inner frames to case the LEDs, so that the light would not disperse through the wrong cut outs.

We debated different solutions to get different colors of light through the different cut outs:

- White LEDs with colored filters

- Colored PMMA filters

- Lamp filters

- Baking paper with colored LEDs

- LED strip with programmable colors

R & D

Report writing. Updating protomap and prototypeplanner. Joined the other teams for supplementing knowledge and thoughts, that could help specify part solutions.

F & E

We further improved the code and tested the master/slave setup.

We also did some initial work in cooperation with the rest of the team to initiate the implementation of the LED functionality – both physically and in the coding.

We decided to go with an LED strip with individually controlable RGB LEDs