BeerWell – video Presentation:

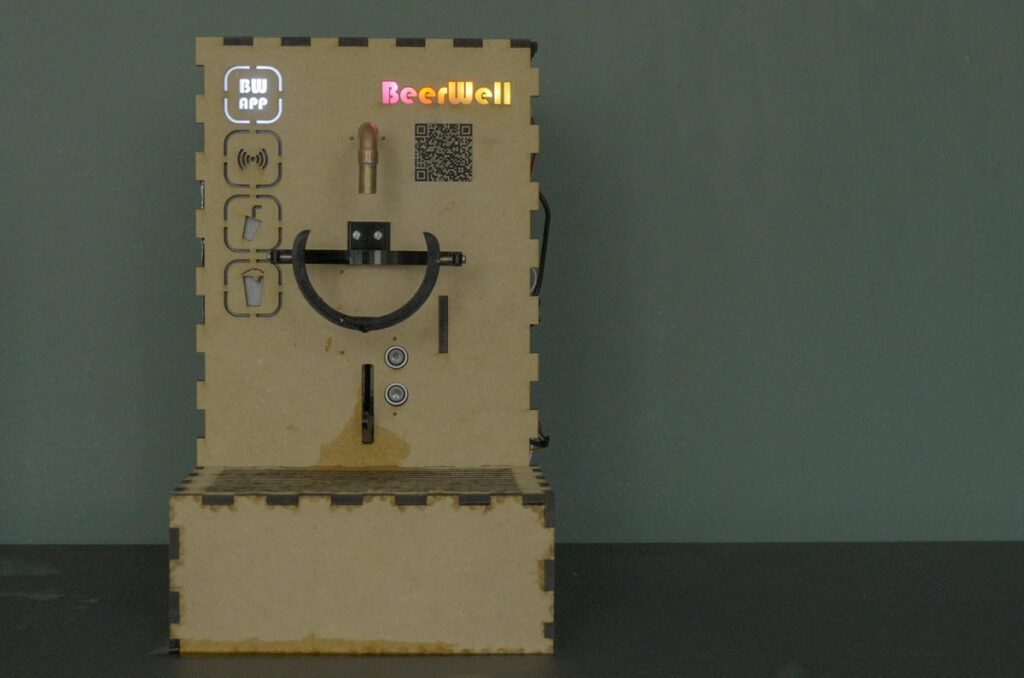

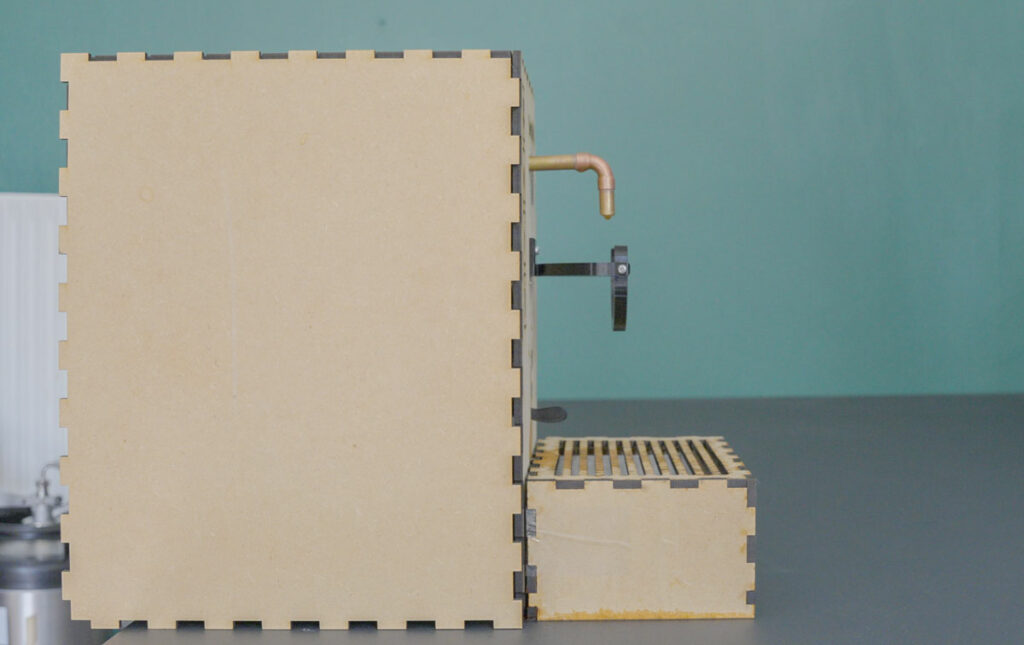

The final prototype:

The final prototype ended up working as intended and we were satisfied with the result. It was, of course, a compromise compared to any ambitions for such a product in a real world scenerios because of the limitations of the course and access to, among other things, a real tap beer system that we could tamper with during testing.

In that relation we ended up having a lot of ideas for improvements for future work:

- Updated plumbing

- Static power supply

- Fittings for a real tap beer system

- A more simple user interface (without app)

- An updated anti-foam functionality

- A lot of user data collection to qualify the solutions

- A more simple electronics setup using a simple PCB

- Fewer and better secured components

- More standard components as mechanics

Just to mention a few.

Delieverables

Design Brief/PRD

https://docs.google.com/document/d/1BMUfx0B1GcWeECmN7GhQo05ioyWHnuR58XXamMpnowc/edit

Protomap:

Prototype planner:

Komponentliste/BOM:

https://docs.google.com/document/d/1ojNcnjNRFjISTSaocjmlm4loMsKLLqbA9UA_oJD2lwk/edit

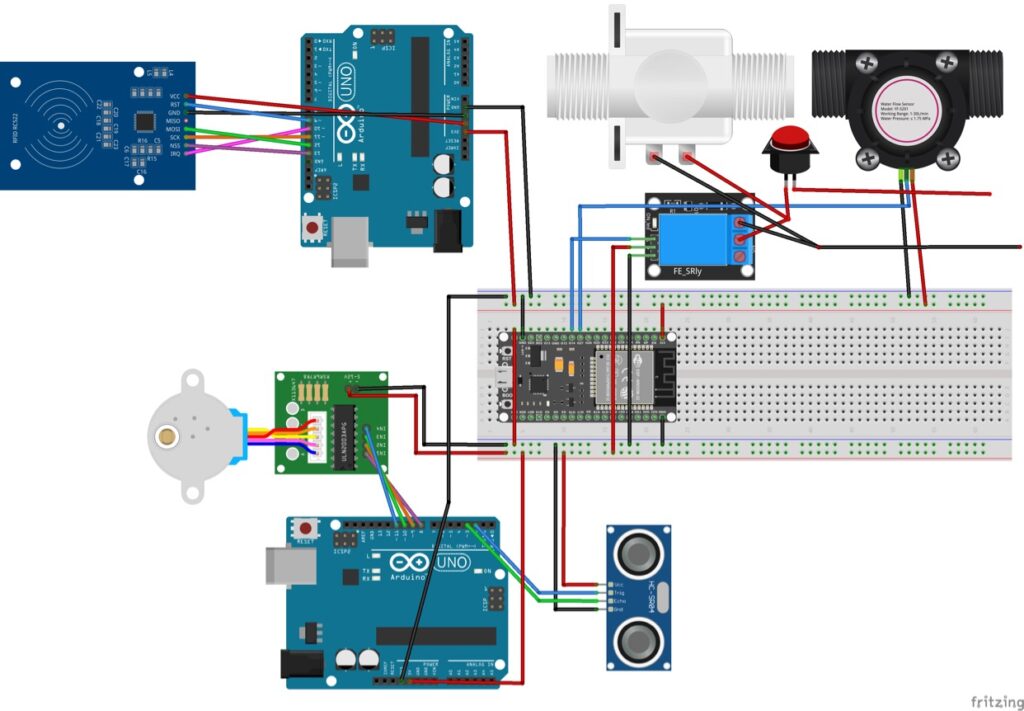

Fritzing diagram:

https://drive.google.com/file/d/1MaAA_LTf3Sl3caAb2BFkDQIXg-47G1aG/view?usp=drivesdk

The process:

We had a quite dynamic team. We followed the SCRUM process. We divided our selves into sub-teams. The teams had good coordination and we managed to meet deadlines and improve on our product through the sprints.

On the critical side we could have had a more controlled progression, that followed a more systematic analyze and ideation process. This could probably have given us a better overview over the extremely many possibilities for solutions to this quite complex product. This could be an approach to future work, but generally we are happy about the work and experience.