R & D – june 6th

We are looking at prototypes for the anti-foam-function

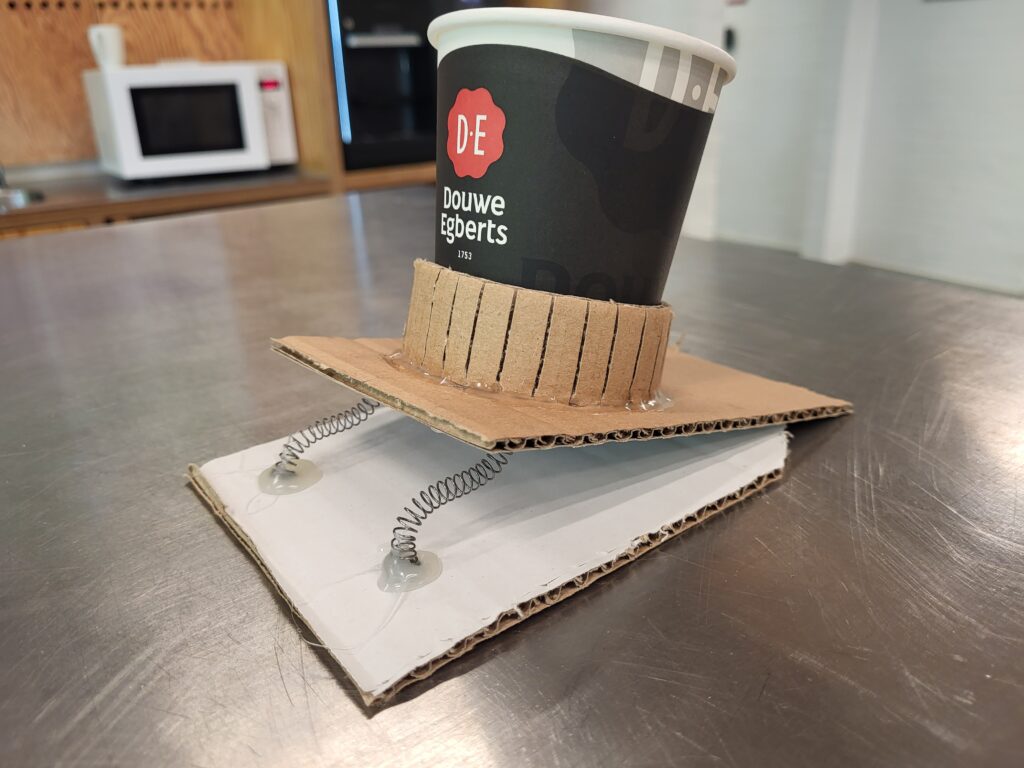

Prototype 1: The first prototype is a cup holder on a plate with springs underneath. The Idea is to start the cup in a 45° angle and let the weight of the fluid press the springs that will allow the glass to end standing up straight.

After testing the prototype we concluded that this solution would not work. The springs were to hard and the were not compressed properly. Instead they were pushed to the side. The cup would end up in an angle even if the springs were compressed fully.

Prototype 2: Next iteration was an arm functioning as a cup holder. Fixed on the casing. Again starting the cup in a 45° angle. As the cup was filled the spring would strech until the cup was held up straight.

We reworked this prototype a few times before testing

It seemed to proove the concept so we decided to reiterate on this solution.

Prototype idea 1: This idea diverts from using springs. Instead the angle will be controlled by a servo-motor that angles the cup relative to the actual volume of beer poured.

Prototype idea 2: This solution depends on the user holding and angeling the cup. With a simple manuaI and or some behavioural design included in the case design. For example some icons/images and limited possibility for placement of the cup.

Prototype idea 3: This solution is the same as the latter. The difference is that there would be a voice guiding the user through the process. The voice would be synched with the functionality.

F&E – june 6th

We went to the hardware store to find the adapters/fittings/parts needed to install BeerWell on a real tap beer system for testing and to implement the flowsensor into the system. We came back and succeeded in establishing those connections. It is not the plan to test with real beer before week 3.

Also we worked on getting a usable output from the flowsensor to ensure the correct volume poured. This was also achieved, but further work is needed to calibrate this to the Solonoid valve to ensure the correct stable amounts poured.

C & F – june 6th

Firstly we Further specifiyed the structural requirements and subfunctions of the casing and framing.

These are the requirements that we found:

Technology aspect:

- Protect inner components

- Fix and secure inner components

- Fix BeerWell to table/bar

- Allow access for power cord (hole)

- Allow beer in and out flow (holes for hoses/tubing)

- Hold glass (evt.)

- Collect drippings/overflow

- allow room for on/off switch

Human aspect:

- Instruct the user (behavioural design)

- Instruct the owner (behavioural design)

- Include affordance for payment (easy to understand)

- Include affordance for placement of cup.

- Include affordance for usability.

- Make BeerWell visible in a bar setting

- Tamper-safe

- Facilitate cleaning/emptying

- Online documentation/User guide(s)

Business aspect:

- Optimize casing in relation to production price

- Optimize material usage and products size for transportation

- Estimate servicecosts of frame and casing

- Optimize aestethics/design/ Object of Desire.

Prototyper to be made:

- Casing design

- Frame design

- Drip tray

Trade-offs to be considered:

- Materials

- Form

- Durability

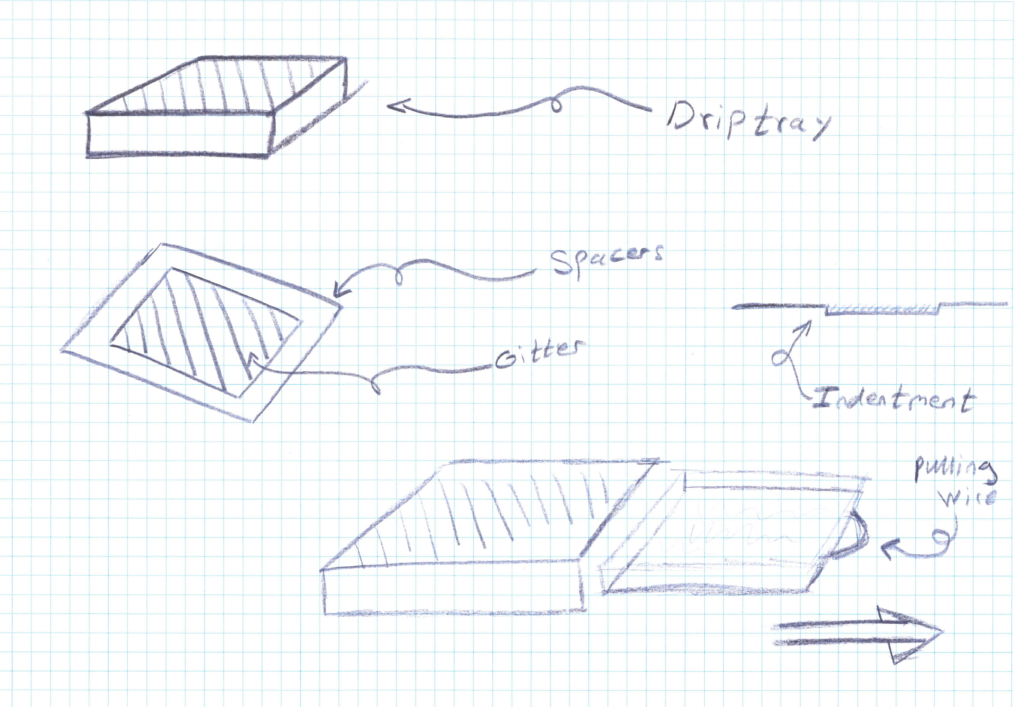

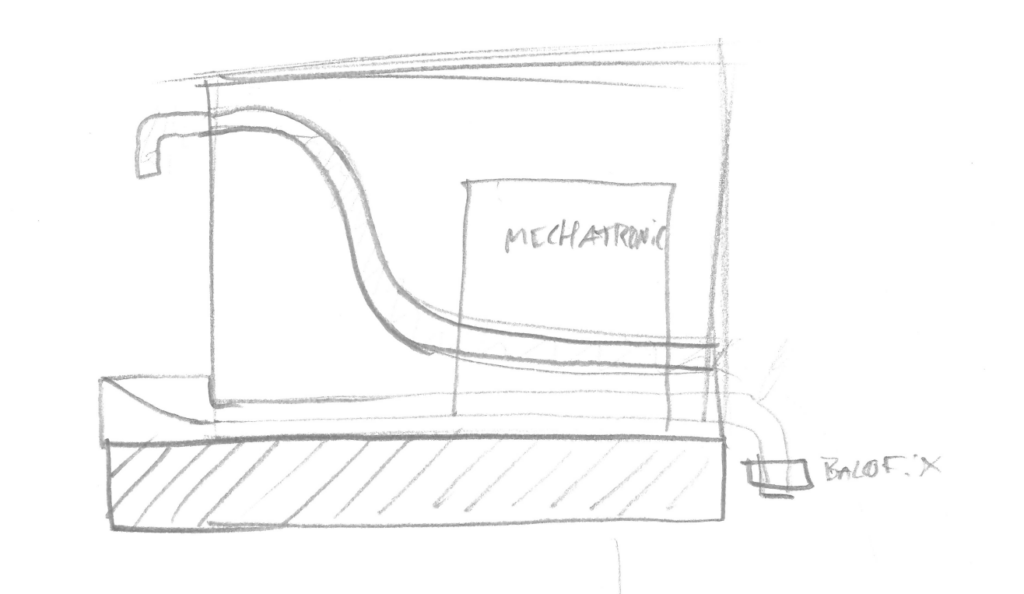

After creating this inital overview, we modelled drew different solutions.

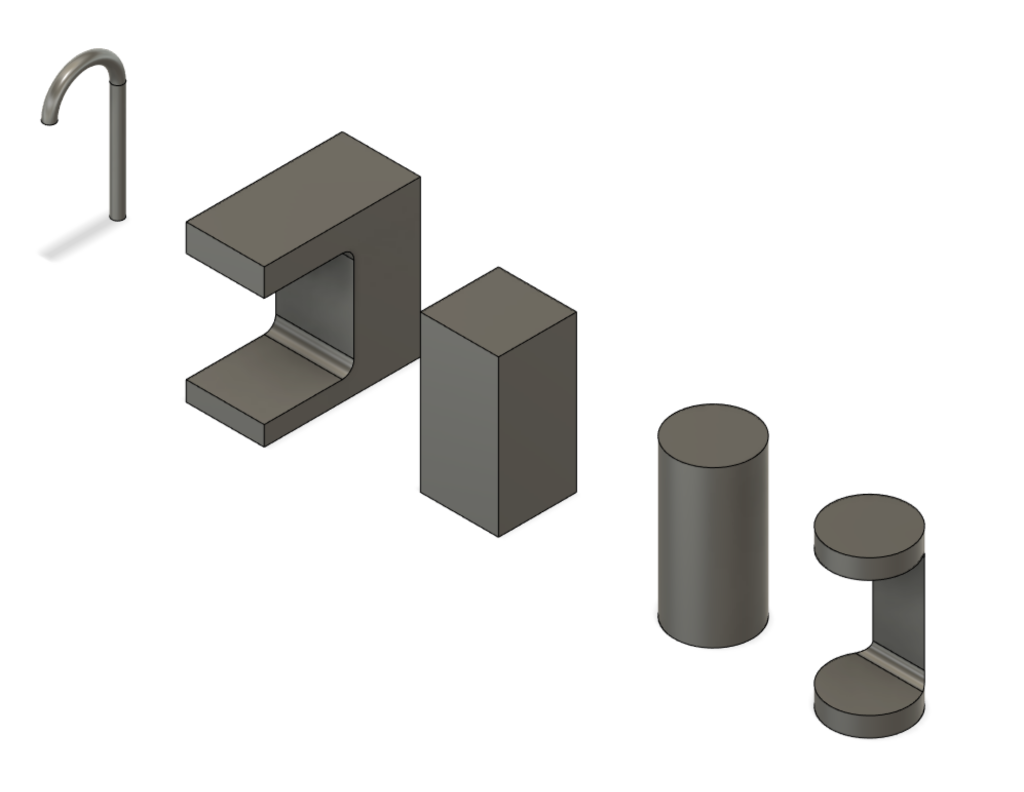

This included CAD-models of the general shape:

Drawings including different partial solutions:

And for fun and inspiration we also did a short prompt on Dall-E (openai):

This deepened our understanding and “debate” about what solutions was to prefer over others.

The criterias chosen was primarily derived from the user/owner- and production aspect. This reflects the above mentioned points about usability, affordance and protectiveness of the casing and framing as well as the production possibilities. We tend to lean towards using sheet metal (cutting/bending) and/or injection molding a hard polymer casing. There are many pros and cons for both these methods and we definitly have to get close to the functional layout of the system before we can qualify the final solution. Thus we need to build and test more low-fi prototypes before we can answer this.