R & D – 07/08.juni

We further iterated on the anti-foam concepts.

We debated the prototypes and did some further brainstorming to include more ideas.

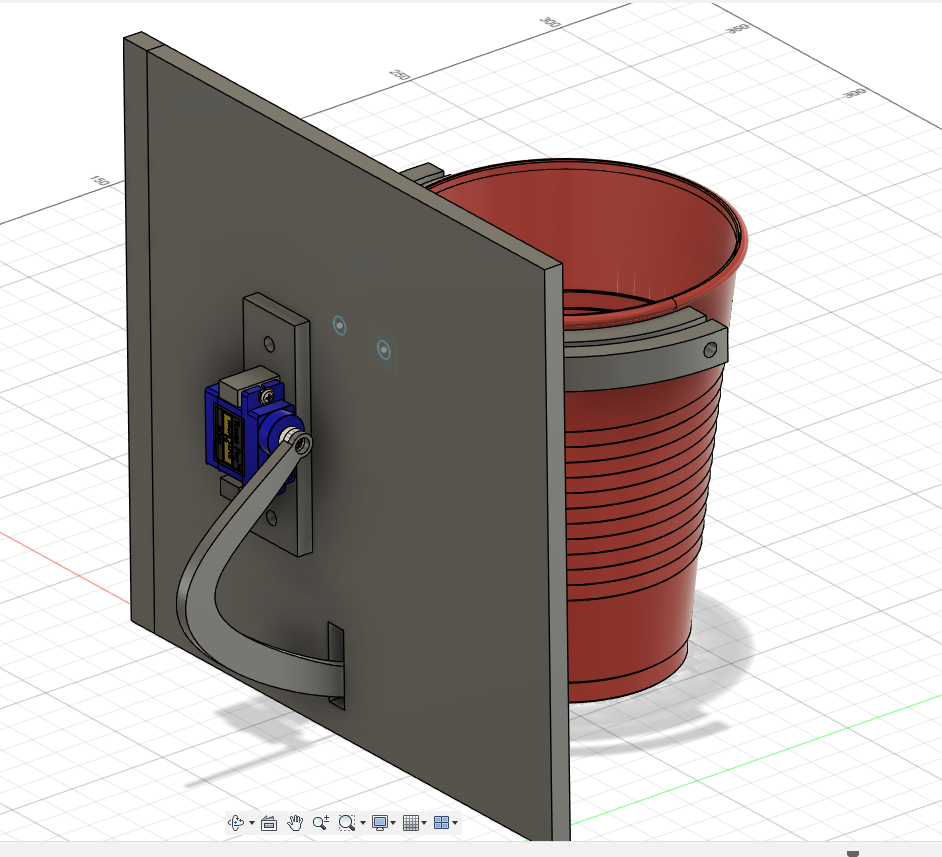

Prototype idea 4: This idea is a combination of concept of Prototype 1 but including the servo motor from Prototype idea 1 to replace the springs. Again it is synched with the volume of beer poured. Instead of the mechanism being fixed to the bottom it is fixed to the “wall” of the casing.

The prototype was modelled in CAD and 3D printed:

Se evt. Billeder “Holding mechanism og pushing mechanism”

https://drive.google.com/drive/folders/1_K5Fg6j896jnu4wKDBRFt3ScQrY6zMJq?fbclid=IwAR3GAPUNVgjrgzJIE4Nmyzr1SXzDXfNLzVWc78RzEbO6lMo0CLBAQLORCp0

https://drive.google.com/drive/folders/1_K5Fg6j896jnu4wKDBRFt3ScQrY6zMJq?fbclid=IwAR3GAPUNVgjrgzJIE4Nmyzr1SXzDXfNLzVWc78RzEbO6lMo0CLBAQLORCp0

Diffent pushing mechanisms was tested and the best was chosen.

Prototype idea 5: The idea is to prevent foam by extending the fosset to the bottom of the glass and fill it up from the bottom. This should decrease the speed of the beer and the fluid should behave more calm and create less foam. This showed to give a new problem – beer stuck on the outside of the tubing getting transported into the machine it self at the end of each sequence. It gives a cleaning problem and it will increase the risk of inner damage and malfunction of the machine – both electronics and mechanics.

C & F – 07/8.juni

Valg af en casing form

We have chosen the above general shape. It lives up to most of our requirements:

- It has smooth surfaces which facilitates cleaning

- It has general shape that can be manifactured from either injection molding or sheet metal bending. Also a minimal shape that can save material

- It has a simple look that opens aestethic possibilities

- It includes a drip tray

- It has room for alle the electronics, mechanics, and their respective in- and outputs.

- It’s size also makes it visible, and facilitates spacing between the outer frame and the inner components to minimize tampering

- Fixtures can easily be added

- It has room on the front to place logo and instructions

F&E – 07/8. Juni

In the process of finding the best anti-foam-function a servo motor was added. We have worked on adjusting the code to facilitate this. To synch the angle with the pouring.