Friday was BIG WORKING DAY. We realised that we lacked some important hardware and features for the requirements. We updated the design-brief. We prototyped. We coded. and we had fun. For details, please read the whole post.

Wednesday surprise

One vivid mind noticed that we were not living up to the requirements given.

That resulted in some interesting changes to our design on friday. Also this was reflected as changes in our design brief. Basically we had to build in some engine feature and some more functionality.

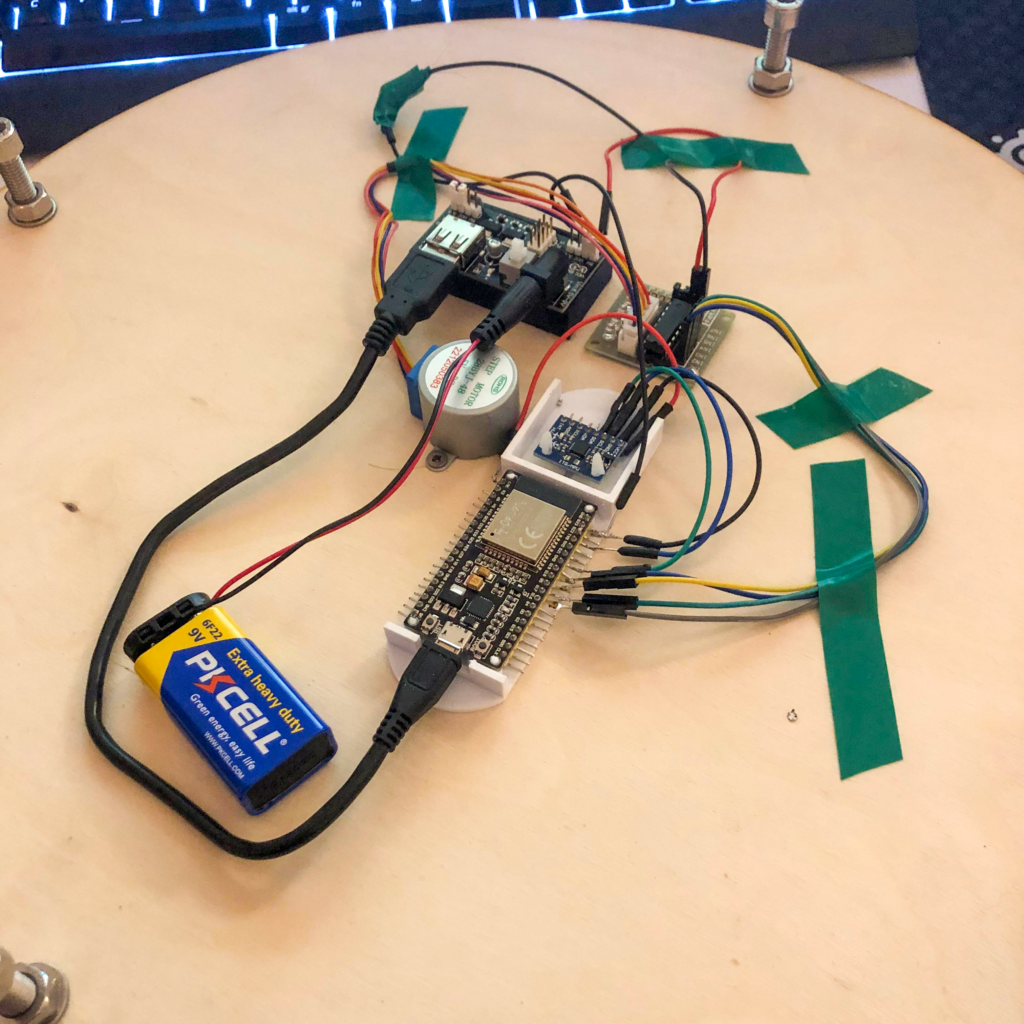

We decided that the indication of the tray’s angle should be an motor-driven pointer. This way the waiter can always see the exact direction were the maximum slope angle is reached, and then adjust the handposition. To see the indicator, we had to produce the tray-top out of a transparent material. We chose to laser cut

Prototyping

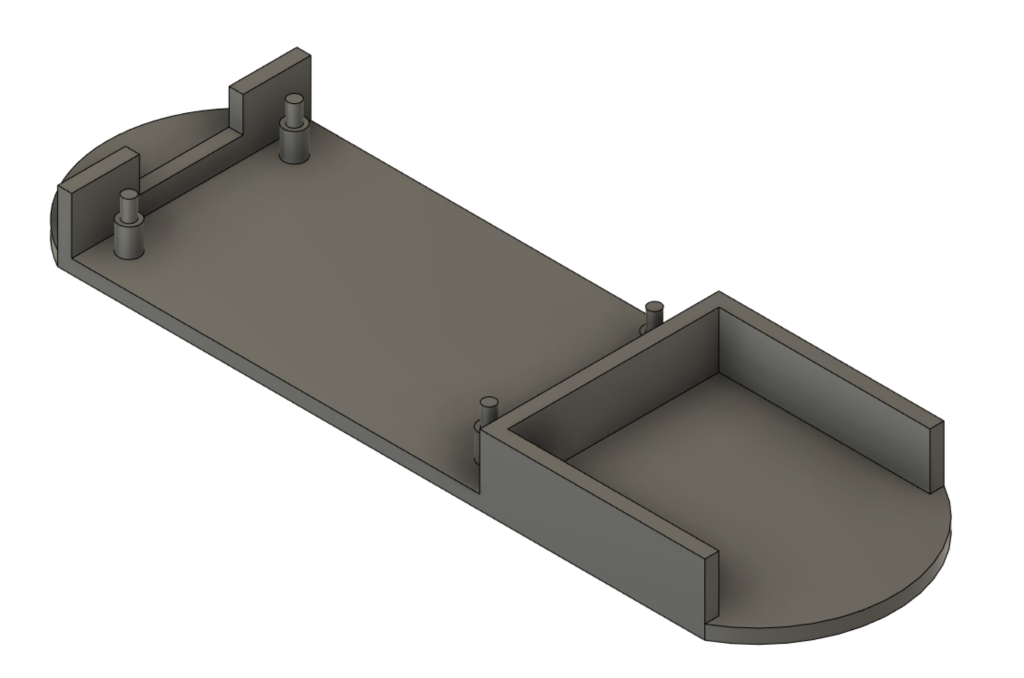

We made a basic mockup of the concept in Fusion 360.

We exported the basic shape of the tray into illustrator so we could laser cut the shape out of cardboard. After laser-cutting the shapes and assembling them with nuts, bolts and washers we decided to make them out of PMMA and plywood.

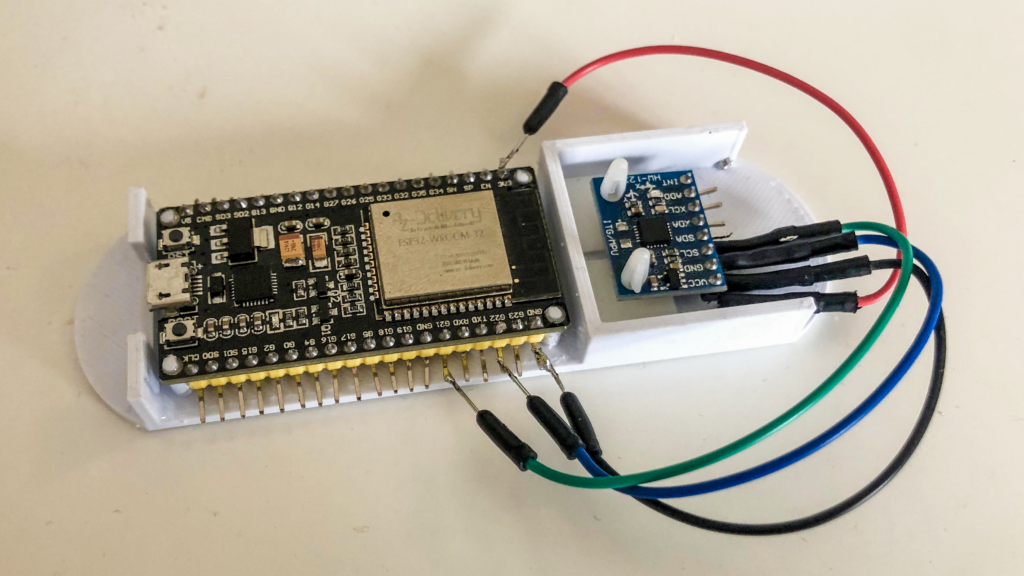

We experimented with relative positioning of the parts (electronics etc). And also added a 3D-printed mount for the electronics.

We then combined it all and made a version in plywood and PMMA.

From this prototype we could see that we needed to ad an indicator showing if the angle was ok. Since the pointer/hand would always point in some direction.

Coding

We managed to make the logging work. The connection to the app was still not working. We also planned how that should be working.